The center in the back of the “Jian Ri Zhi Guang” Light Penetrating Mirror collected in Luoyang in 1953 is decorated with a circular knob on a base surrounded by the bow string pattern. The main pattern on the back consists of eight running curves. Eight characters that read “Jian Ri Zhi Guang, Xiang Si Wu Wang” are inscribed on the mirror, and bordered by a circle of saw tooth design on each side. [1]

After some simple processing such as grinding and polishing, the sheeny surface of the “Jian Ri Zhi Guang” Light Penetrating Mirror, when exposed to sunlight or spotlight, can reflect the inscribed characters and images on the back, and was therefore called “light penetrating mirror” in ancient times or “magic mirror” by some foreigners.

The earliest record of light penetrating mirror in China appeared in the mysterious novel by the title of On Old Mirror by Wang Du in the late Sui and early Tang Dynasty. It descried an “old mirror” that “when facing the sunlight, the characters and images on the back show up in the front surface without any loss”. Although a description from a novel, it fully matches the characters of a light penetrating mirror.

Scholars such as Shen Kuo from the Northern Song Dynasty, Wu Qiuyan of the Yuan Dynasty and Zheng Fuguang of the Qing Dynasty all carried out some studies to find out the working principle of a “light penetrating mirror”.

Shen Kuo, a scientist in the Northern Song Dynasty, believed that an object’s thermal expansion nature contributed to the penetrating light in these old mirrors. According to him, for the same type of materials, the bigger the size, the larger the deformation caused by heat or cold, which resulted in expansion or contraction. Therefore, when the bronze mirror was subject to a cooling process after it was cast, the thinner part contracted less than the thicker part. As a result, part of the surface of the mirror sagged to form an image similar to the characters and images on the back of the mirror. He also found out that other bronze mirrors, although very thin, did not allow light to penetrate. Consequently, he believed that ancient people were able to make light penetrating mirrors by other methods.

According to Wu Qiuyan of the Yuan Dynasty, after a bronze mirror was cast, the images similar to those in the back were cast (incised) on the surface, the concave was filled with “bronze of slightly inferior quality”, and the surface was flattened before lead was applied.” When the finished bronze mirror was held against the sunlight, it penetrated the mirror made of bronze of different quality to display different brightness. This is called mosaic method.

Zheng Fuguang, a scholar in the Qing Dynasty, believed that “due to the difference in thickness on the mirror caused by decorative patterns, the thinner part cools down faster than the thicker part. The same material with different thickness determines that when the mirror is heated, different parts expand at a different speed, showing some indistinct convexity on the surface.” Such an “indistinct convexity” caused by different thickness “may not be completely removed when the surface was scratched with force of varied degree as a result of the existence of convexity”. The craft of “grinding” could not smooth the surface to an “extreme level” as only a small layer of the surface was ground off. [3]

The study of the light penetrating mirror by the Westerners started from the 1930s when Principo spotted a “magic mirror” by accident in Kolkata and made a description of the mirror in Asian Journal. The European scientific community had since carried out the research and discussion on why light penetrates through the mirror that lasted for a century until Prague made a convincing explanation of “magic mirror” in 1932, i.e. the amplification effect of long optical path.[4]

In summary, scholars of different times have attributed the following four points to the light-penetrating property of the mirrors: First, the shape of the bronze mirrors. The overall light-penetrating bronze mirrors raise with a wide and thick rim, a thinner body and patterns in concentric circles; Second, the curvature differentiation caused by the residual stress in the casting process is the fundamental reason; Third, the quenching stress caused by the quenching treatment of the bronze mirror is one of the reasons for light to penetrate; Fourth, the grinding technique is an important factor that contributes to the light-penetrating property of these mirrors. The casting residual stress inside the bronze mirror is not enough to create the needed deformation. Only by continued grinding, can the bronze mirror be made thinner and the residual stress be released to create a big enough convex deformation on the surface of the mirror.

The light penetrating mirrors are made with superb technology and craftsmanship that fully utilize and reflect the principles of optics and mechanics. They are highly valuable in the research of history, science and art and are the most precious kind of mirrors in the Western Han Dynasty and one of the finest Chinese historical artifacts.

A “Jian Ri Zhi Guang” light penetrating bronze mirror of the Western Han Dynasty that is now in the collection of Shanghai Museum (Fig. 3) measures 7.4cm in diameter and weighs 50g with a wide and thick rim. In the center of the back is a round knob surrounded by a circular pattern of eight running curves, outside which are inscriptions of eight characters that read “Jian Ri Zhi Guang, Tian Xia Da Ming”[7]. The two adjacent characters are separated by cirrus pattern or a Chinese character of “田”.

A “Nei Qing Zhi Yi Zhao Ming” Light Penetrating Mirror of the mid- to late Western Han Dynasty now in the collection of Shanghai Museum (Fig.4) measures 11.5cm in diameter and weighs 280g with a wide and thick rim. On the back of the mirror are two circles of patterns as well. The inner one consists of a ring, eight running curves and a round knob in the center. In the outer ring, there are inscribed characters that read “Nei Qing Zhi Yi Zhao Ming, Guang Xiang Fu Ri Yue”, with two adjacent separated by the Chinese character of “而”. [8]

A “Jian Ri Zhi Guang” Light Penetrating Bronze Mirror of the Western Han Dynasty now in the collection of Pingxiang Museum of Jiangxi Province (Fig.5) measures 6.9cm in diameter and 0.5cm in thickness. The mirror has a slightly convex surface, a nose-shaped knob, and a persimmon-flower-base shaped knob base. The bas relief decorations are divided into four sections and all separated by thin convex bow string pattern. The outer section is decorated with the pattern of diagonal comb teeth. The second has an inscription reading “Jian Ri Zhi Guang, Tian Xia Da Ming”, with characters separated by cirrus and Chinese character of “田”. The third is decorated by the pattern of diagonal comb teeth. The inner section is decorated with the pattern of eight inward running curves and four nipples.

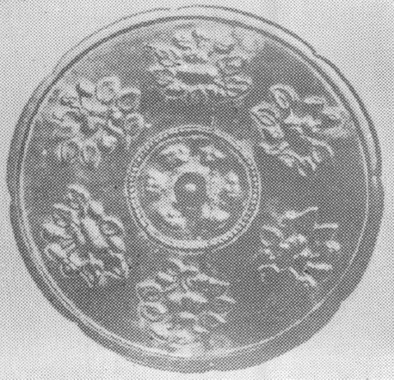

The Cultural Center of Suiping County has two light penetrating mirrors with rosette design of the Tang Dynasty. The first one (Fig. 6) was unearthed from the river embankment restoration construction site in Yue’erwan in Suiping County. It measures 16.9cm in diameter and weighs 500g, with a semi-circular knob being 1.5cm in diameter. On the back of the mirror are seven flowers in full bloom, one in the center and surrounded by the other six[10]. The other one is an octagonal light penetrating mirror with rosette design (Fig. 7) that was unearthed from a tomb at Renmazhuang Village of Zhushi Township in Suiping County. It measures 17.9cm in diameter with a semi-circular knob and a protruding rim being 0.3cm in thickness. On the back are seven flowers, one in the center and surrounded by the other six. [11]

In summary, the light penetrating bronze mirrors mentioned above include the “Ri Guang” Mirror and “Zhao Ming” Mirror of the Han Dynasty and the Mirror with Rosette Design of the Tang Dynasty. All the three kinds of bronze mirrors differ from the other bronze mirrors in the following aspects: 1. A wide and thick rim; a very thin mirror body measuring merely 0.5-0.9cm in thickness; 2. A slightly convex surface, a correspondent curvature on the surface and back of the mirror; a mirror body of even thickness except for the patterns that are arranged symmetrically on the surface and back.

The light penetrating mirrors of the Han Dynasty also differ from those of the Tang Dynasty due to the different casting technologies and levels of social and economic development. The back of the light penetrating mirrors of the Han Dynasty has inscriptions and running curve patterns that are simple. The convex inscription gives a sense of solid existence. The light penetrating mirrors of the Tang Dynasty, on the other hand, are decorated on the back of the mirror with the rosette design that demonstrates the most distinct noble character. The patterns are of a magnificent style that reflects the graceful, lively and flourishing artistic conception.

Based on your knowledge, which principles of optics and mechanics were used by the ancient people to make the light penetrating mirrors?

Your answer please, if you have any questions or answer, please feel free to send us email, we are waiting for your answers and participation, and your comments, answers and suggestions will be highly appreciated. We will select and publicize the most appropriate answers and comments some time in the future.

Weekly Selection Email: meizhouyipin@chnmus.net

The Alloy Composition in Bronze Mirrors of Different Periods in the Chinese History

The percentage of bronze and tin in bronze mirrors of the Qijia Culture is 1:1.096.

The mirrors of the Shang and Zhou Dynasties have slightly higher tin content, but the quality is far inferior to the ceremonial bronze wares of the same period. They also lack necessary rust prevention processing to the surface.

The percentages of bronze, tin and lead in the bronze mirrors of the Warring States Period are relatively stable with bronze at the level around 68%, 74.8% at maximum and 56.6% at minimum. The percentage of tin is generally at around 20%. Lead takes the percentage of 0.45%-3%.

The alloy percentage in the bronze mirrors of the Han Dynasty is stabilized with bronze at 60-70%, tin at 20-24% and lead at 4-6% generally.

The mirrors of the Tang Dynasty especially those of the flourishing period of the Tang Dynasty display the color of silvery white and have a relatively stable alloy composition with bronze at 69%, tin at 25% and lead at 5% on average.

The alloy composition of the mirrors in the Song, Western Xia, Liao, Jin and Yuan changes significantly. Tin is reduced to 10% while lead is increased to above 8% and maybe as high as 23.7%, much higher than the percentage of 5% in the mirrors of the Tang Dynasty. Tin is increased as well to 8% at maximum.

Most of the mirrors in the Ming and Qing Dynasties display a yellow color with copper taking 70-75% and zinc at 25-30%. As alloy of copper and zinc often shows a color of yellow, it is also called brass. The relationship between the color of the alloy of copper and zinc and the content of zinc is: red with yellow at 10% of zinc, yellow with red at about 15% of zinc, yellow at 25% of zinc and dark yellow at about 30% of zinc. [12]

Basic Techniques in Casting a Bronze Mirror

1. Casting from the top:

In ancient China, the traditional way of casting metal objects was by clay mould in most cases. Stone moulds were also used in some circumstances. The mould pieces were first fired and then cooled down completely before they were pieced together and used for casting metal objects. Preheating of the mould was necessary before casting to prevent sub-standard products. When casting, the temperature should be kept from getting too high, which not only reduced the air-absorption problem by the cast metal objects but also prevented sintering the surface of the mould to ensure the cast metal to come off easily and the quality of the mirror. Generally speaking, the flow gate is designed well to facilitate the flow of the metal fluid.

2. Special casting method on open-work mirrors

The special casting method was mainly used for casting two-layer open-work mirrors, whose surface and back were made of different alloys that were inlaid together. Normally, the back of the mirror was inlaid in the surface, namely, “surface of the mirror” wrapped the “back of the mirror”.

3. Heat treatment technique for bronze mirrors

Bronze with high tin content is both hard and crisp. In the Warring States Period and the Han and Tang Dynasties, people often put the alloy through a quenching and tempering treatment to improve bronze mirrors processing and usability. This was a process that started after the mirrors were basically cast and cleaned up simply. Seen from modern technical principle, bronze with high tin content was both hard and crisp before quenching. The quenching process improved its plasticity and material strength while decreased the hardness. The tempering temperature affected the hardness of the material, i.e., the lower the temperature, the higher the hardness.